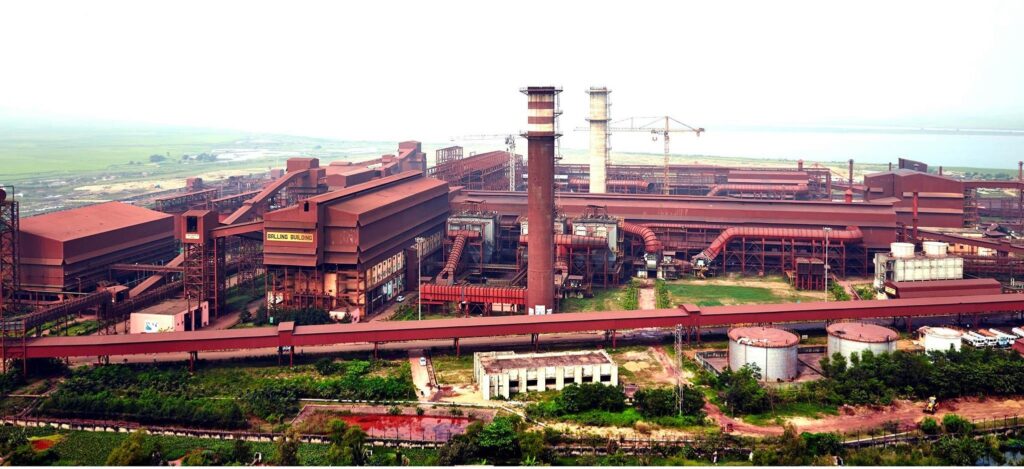

EnerTech has always been at the forefront when it comes to implementing new technologies. Recently, EnerTech has installed the latest EnerTech 110V 150A Battery Charger for ArcelorMittal Nippon Steel India at their Surat facility. To ensure better performance of their operations and reliability. This represents the accomplishment of a great milestone and the determination of EnerTech to meet the client’s industrial needs with innovative solutions customized to suit their requirements. Now, we will look into how EnerTech offered a comprehensive solution and delivered the project perfectly.

Understanding the Challenge

ArcelorMittal Nippon Steel India, Surat, a leader in the steel industry sought to enhance its efficiency by installing its battery charging infrastructure at the Surat plant. The challenge was to find a solution to address the particular power needs of the facility while achieving the goals of reliability, efficiency, and safety.

The issues of steel industries in their battery charging setups for equipping industrial gadgets are that some of this energy is wasted and efficiency is either compromised for the worse or the best. Here are some common problems faced by steel companies in battery charging processes:

- Inefficient Charging Infrastructure: The charging equipment that is old or obsolete could prove to be imprecise, making the charging process more prolonged and therefore energy-consuming. Charge inefficiency may be the cause of broken energy and the company is likely to spend more for its operations.

- Voltage and Current Compatibility: Getting the correct voltage and current passes has been a big part of the charging process for industrial batteries. If the battery charger output voltage or current is wrong, it results in an undercharge or overcharge, then reduces life span and utilization efficiency.

- Poor Power Factor: Consuming reactive power is one of the problems with a bad power factor. Such a can result in more energy bills and a loss of efficiency of the whole system.

- Battery Health Monitoring: Batteries can lack efficiency if they’re not properly tested and repaired. Gradually, the battery’s performance degrades and its capacity lessens. The smooth and longer time of battery performance for Steel companies demand reliable battery health monitoring systems so that optimal performance and longevity can be ensured.

- Environmental Factors: The unique conditions of space and the fact that there might be extreme temperatures or the contamination of the equipment can reduce the resilience of the items and shorten their life span. Regarding environmental factors, steel company managers need to address battery charging in terms of their design and implementation.

- Safety Concerns: Creditable but not sufficient electric battery charging systems can also create a danger to people and property. Safety risks like overcurrent, short circuit, or overheating can lead not only be the cause of productivity clogs but also dangerous events. Downtime, on the other side, will decrease productivity, which will eventually impact the profitability of the business.

To address these energy wastage issues and cut the same, steel industries will require advanced, energy-consuming friendly, and productive battery charging systems. Through the installation of modern charging equipment, implementation of energy-efficient technologies, and focus on preventive maintenance alongside monitoring, steel companies can improve their system of charging batteries, cut down on energy consumption, and have operationally efficient processes.

EnerTech’s Tailored Solution

The EnerTech team including experts provided them with the required inputs and help they needed to explain their needs and challenges. Referring to the long-term cumulative knowledge of power electronics, EnerTech created the solution which was built around the installation of the top-notch 110V 150A industrial battery charger.

Key Features of the Industrial Battery Charger Solution

- High Power and Voltage Capacity: The DC Industrial Battery Charger offers high power delivery as well as sufficient voltage capacity to contribute to the heavy tasks of ArcelorMittal Nippon Steel India’s operations, and at the same time, ensure that the batteries are charged efficiently.

- Robust and Reliable Design: EnerTech offers its Industrial Battery Charger for the needs of the heavy industry, where indoor environments are characterized by high levels of machining dust, water, sulphur, etc. The design has been developed to make it rugged and highly resistant to industrial wear and tear.

- Advanced Safety Features: One of the main elements to focus on in industry is safety. These devices adopt complicated protective server mechanisms to secure personnel and equipment using overcurrent protection, short circuit protection, and temperature monitoring.

- Efficient Charging Process: The Industrial Batterypowered Charger regulates the charging operation so that your battery will be recharged under the most suitable condition. This system will make it possible to reduce wasted time and maximize productivity.

Seamless Project Execution

The dedicated EnerTech team designed and managed each step of the implementation process, including the remaining part of the technical project, from a site check and selection of machines to testing and entering into operation. Utilizing their professional skills and their close attention to thoroughness, EnerTech was able to provide a hassle-free and seamless upgrade to the battery charging facilities.

Certainly, here are the technical features of EnerTech’s Industrial Battery Charger presented in bullet points: Certainly, here are the technical features of EnerTech’s Industrial Battery Charger presented in bullet points:

- High Power Capacity: Able to serve [specify the power range] to new industries, whose requirements may be very demanding.

- Adjustable Voltage Output: This provides adjustable voltage for different battery types from highly advanced to basic ones and their respective charging demands.

- Current Limiting Functionality: Guarantees safe charging by maximizing the speed of supply of electric charge to the battery, which in turn helps to reduce the occurrence of an excessive charge.

- Temperature Compensation: In some cases includes temperature sensors for charging, setting parameters in response to the surrounding temperature, thereby optimizing the charge efficiency and longevity of the battery.

- Multi-Stage Charging: Establishes different charging pattern advance phases (e.g., bulk, absorption, float) aimed at enhancing battery performance and endurance.

- Digital Display: The display is digital and indicates the charging stage, voltage, current, and temperature, consecutively, by a simple operation.

- Remote Monitoring Capabilities: It enables you to switch on or off remotely and set the charge parameters utilizing digital interfaces or communication methods.

- Fault Detection and Protection: The related driving force for battery EVs and HEV is the built-in fault detection mechanisms and protection features such as overcurrent, short circuit, overspeed, etc. that also ensure the safe operation and guard against damage to batteries and equipment.

- Robust Construction: Often manufactured using heavy-duty materials and components to resist adverse environmental conditions and for guaranteed industrial-grade durability, reliability, and outstanding long-term performance.

- Modular Design: Modular structure provides flexibility and scalability to allow for effortless add-on or alteration of modules according to the specific application needs.

- Compliance with Industry Standards: Respect relevant industry standards and certifications (e.g., IEEE or UL) that guarantee safe operations, quality of service, and satisfactory performance.

Results and Impact

The performance efficiency of the 110V 150A Industrial Battery Charger in ArcelorMittal Nippon Steel India Surat plant has improved substantially after the completion of the successful installation of the battery charger. Thanks to having the reliable and effective charging system in place that facility is ready to operate with minimized downtime, increased productivity and, finally, to implement a general working improvement.

Conclusion

The collaboration of EnerTech with ArcelorMittal Nippon Steel India showcases an intention to not only innovate but to also collaborate and ensure the highest standards.

EnerTech did this by planning and implementing customized commissioning solutions which in turn enabled the power plant to attain its specific operational targets and strive for future growth.

On the whole, EnerTech trusts itself to be just a minor partner in power electronics and achieving the ultimate goal of powering the progress and making up the success of its industrial partners.

Ready to revolutionize your industrial power solution? Contact our expert team today at +9370659050 / 9373336340 or drop us an email at sales@enertechups.com. Let’s power your business with innovative power solutions from EnerTech.

Tags: batterycharger, industrialbatterycharger, 110vbatterycharger, 110v150ampbatterycharger, 110vdcbatterycharger, 110vdc150ampbatterycharger, 110v150aindustrialbatterycharger, 110vdcindustrialbatterycharger, 110vdc150ampindustrialbatterycharger, arcelormittalnipponsteelindia, arcelormittalnipponsteel, arcelormittalnipponsteelsurat